Gronda di Genova

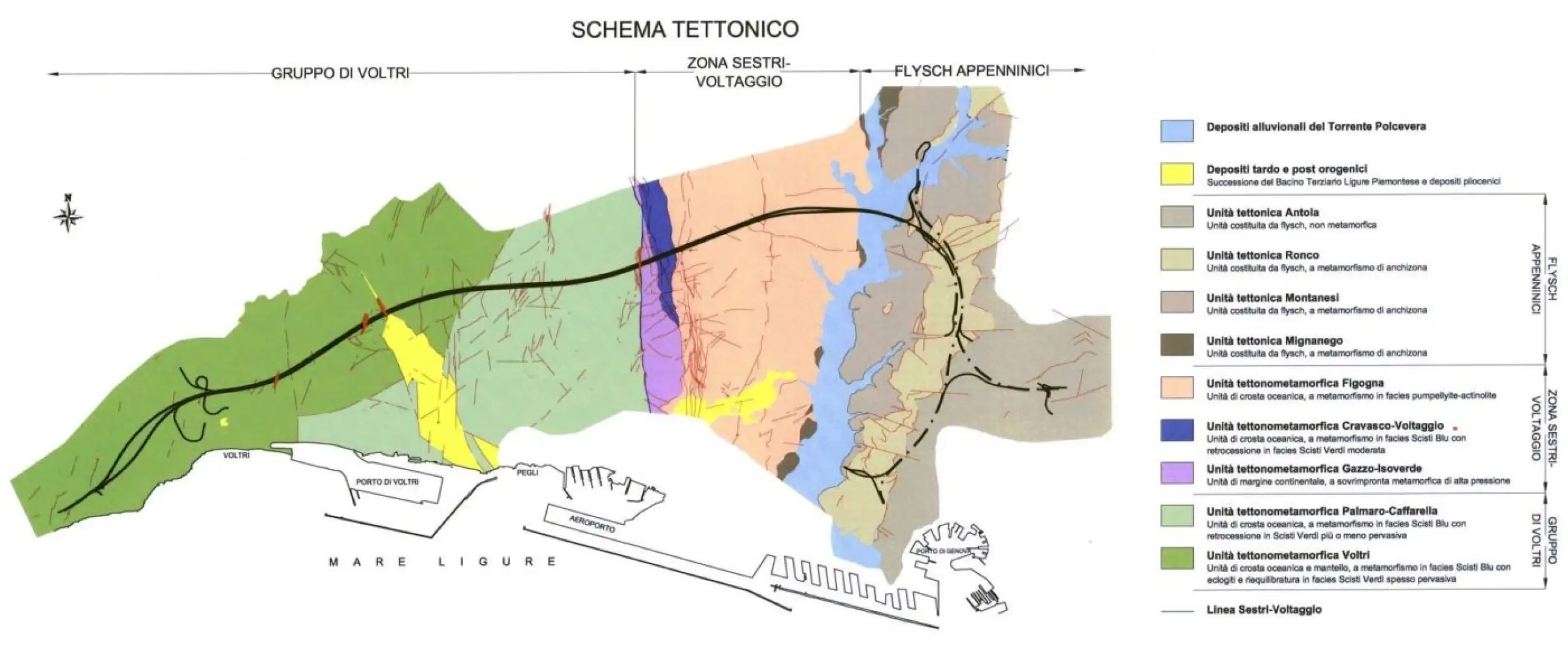

Given the particular structure of the Genoese territory, the new road system will be developed almost entirely underground, involving the section called the 'Sestri Voltaggio Line', in correspondence with the Polcevera Stream, which marks the physical boundary between the Apennines, consisting mainly of sandstone, clay, limestone and marl, i.e. sedimentary rocks, and the Ligurian Alps, consisting of the Voltri group and the Sestri Voltaggio area, with the asbestos-bearing rocks and heavy metals.

The particular geological conditions of the terrain crossed by the infrastructure have led to the provision of 'traditional excavation' technologies for the tunnels to be built in the less problematic formations east of the Polcevera Stream, and mechanised excavation technologies for the more critical portions of the territory (western area of the Polcevera Stream).

The conventional excavation was mainly reserved for tunnels that are not affected by asbestos geological formations - i.e. all those to the east of the Polcevera Valley crossing - and for tunnels that, due to their limited length, small cross-section or the tortuosity of the route, are not suitable for mechanised excavation. The 'hammer', a hydraulic drill mounted on large excavators, will be used for these excavations.

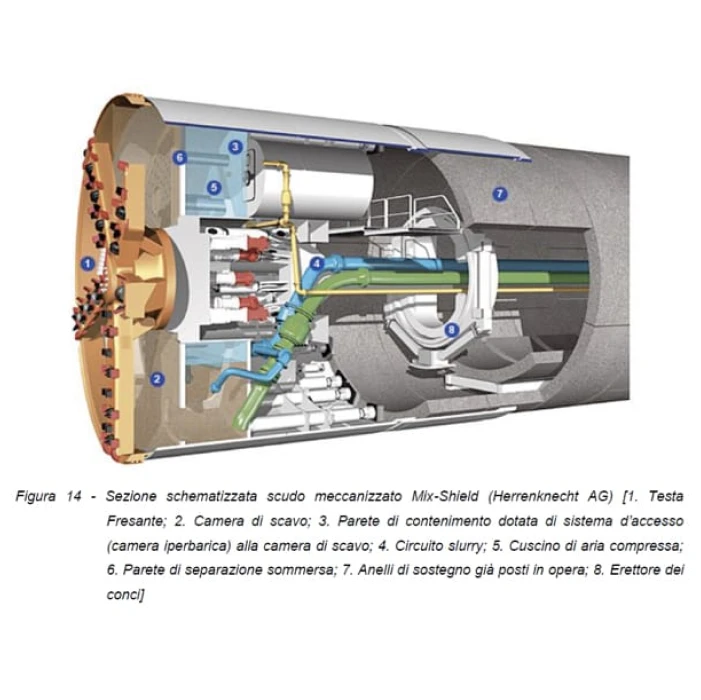

The TBMs (commonly known as 'moles') chosen for the excavation of the tunnels west of the Polcevera Stream are of the Hydroschield (HS) type, i.e. cutters that use a bentonite fluid that combines the soil and rocks being excavated. This excavation method was chosen because it can guarantee constant pressure at the machine head and 'wet' transport of the material, avoiding dust dispersion. TBM HS also reduces progress times and construction costs because it allows progress of more than 10m per day, unattainable with traditional excavation methods.